06/26/2024

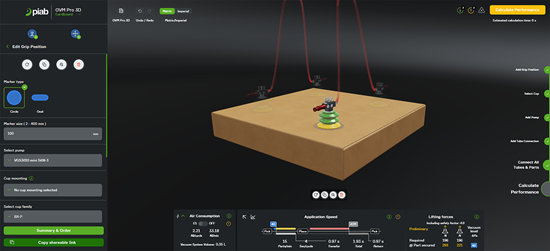

Piab has launched its highly anticipated OVM Pro 3D, a cutting-edge online tool designed to transform the way vacuum systems are configured, simulated and optimized.

Piab has launched the OVM Pro 3D, an online tool that leverages advanced 3D modelling and simulation to streamline the vacuum system design process.

Ever since Piab assumed its leading position within vacuum automation engineering, the company has sought ways to simplify the system design process for all worldwide customers.

“In short, we wanted to make configuration and optimization of vacuum-driven systems available to anybody interested in conforming their processes in that direction,” said Johnny Skagersjö, Senior Application Engineer of the Vacuum Automation Division.

After more than two years of development, Skagersjö and his team can now proudly present the solution. OVM Pro 3D, which stands for "Optimal Vacuum Management Professional," leverages advanced 3D modelling and simulation to streamline the system design process on-line, offering a range of benefits from control and efficiency to significant cost savings.

"OVM Pro 3D represents a major leap forward in DIY configuration and optimization of vacuum systems. Our focus on user experience and detailed performance data aims to make the process more intuitive and error-free,” said Josef Karbassi, Acting President of the Vacuum Automation Division.

The OVM Pro 3D software will be provided in an open format on https://www.piab.com and packed with features aimed at improving user experience and enabling detailed performance insights. Some of the standout features include:

Complete design: After login, the design process takes off from the user’s enterprise and process needs, offering full integration of Piab’s extensive range of vacuum ejector pumps, suction cups, grippers, fittings and accessories.

Text and symbols guidance: Detailed guidance is provided throughout the design process, including descriptions and technical data such as actual compressed air ranges for selected ejectors and optimal pressures.

Lifting force graph: This feature displays total horizontal and vertical forces throughout the entire cycle, with separate performance data for suction cups, highlighting the lowest and highest values.

Energy and power consumption visualization: The application visualizes air compressor power usage, helping users understand and dimension the size and capacity of the compressor needed. Estimated daily (eight-hour shift) compressor electricity power consumption is also displayed to support energy cost discussions.

Performance data positioning: Performance data conveniently placed on the left side with a scroll function. Hovering over the data zooms in on the specific product and dims excluded components, facilitating a clearer view of performance data such as time to reach set vacuum level in that node.

Tube length management: Users can directly edit tube lengths, which are marked with a "Z" and locked to maintain their length even if components are moved.

Clear supportive graphs: The graph feature includes a zoom function for better observation during crucial time frames, and a visual checklist ensures all steps are completed before calculations.

Piab continues to innovate and develop, with plans to include more functionalities in future updates.

“For those eager to experience the future of vacuum system configuration, OVM Pro 3D is now available, promising a more efficient, accurate and customizable approach to vacuum handling. However, we will not rest. The work will continue, aiming to eliminate any obstacle that customers may experience when they enter processes like these,” said Karbassi.

About Piab

Piab is evolving automation through progressive gripping, lifting and moving solutions. Since 1951, Piab has been serving industries like e-commerce logistics, food, pharma, automotive and more, improving energy-efficiency, productivity and work environments. With a presence in more than 100 countries, Piab is a global organization dedicated to developing automation solutions that enhance the efficiency and quality of production processes. For more information, visit https://www.piab.com.