06/03/2024

AERZEN has been building turbo blowers since 1911 and has continued to push these packages to the peak of technology over many decades. Today, the Aerzen G5Plus turbo blower series is one of the most compact and efficint turbos of its class. Compared to conventional turbo technology, the energy efficiency is up to 10% higher, and compared to displacement machines, such as positive displacement blowers, savings of up to 30% can even be achieved. With the new AT250 G5Plus, AERZEN is extending the series upwards, making the advantages of efficient turbo technology accessible to an even wider range of uses and applications.

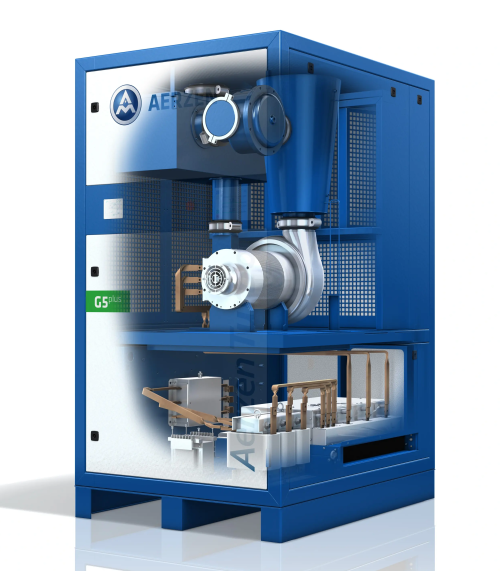

The Aerzen Turbo AT250 G5Plus is a compact plug-and-play package and enables significant energy savings.

The new Aerzen Turbo AT250 G5Plus is rated for a volume flow of 155 m3/min, a maximum differential pressure of 900 mbar and speeds of up to 26,000 rpm and has a very large turndown of 1:4. A powerful and energy-saving permanent magnet synchronous motor, which meets the future requirements of the IE5 classification (ultra-premium efficiency), as well as the particularly aerodynamic design of the turbo impeller and spiral casing ensure a consistently high overall efficiency. Even in partial load operation, the AT250 G5Plus delivers exceptional performance and high power density.

The modern multilevel VFD technology reduces the power loss in the motor by up to 90%, giving it a clear advantage over conventional inverter technology. Further advantages are greater insensitivity to pressure fluctuations and better control behavior. This means that the turbo packages can be operated in a much more stable manner across the total turbo characteristic diagram. The innovative AERZEN air foil bearing with double coating ensures an increased service life of >80,000 operating hours and maximum reliability. The packages are sound-optimized and guarantee quiet operation of 72-73 db(A). In addition, the powerful turbo blowers are 100% oil-free, incredibly robust and child's play to operate. The maintenance requirement is negligible.

AERZEN manufactures and develops all of its products via in-house production. Only in this way can all the components be perfectly coordinated with each other and ideally adapted to the operating process. This means maximum reliability, operational reliability and cost-effectiveness. The AT250 G5Plus is already completely configured and assembled ready for connection when it is delivered on site. Thanks to the compact design, the machine footprint is extremely low. For example, a turbo machine requires only a third or a quarter of the footprint of a positive displacement blower with comparable performance. As a result, the machine room can be a lot smaller.

With the smallest footprints on the market and maximum energy efficiency, the Aerzen Turbo AT250 G5Plus offers compact power that is indispensable for numerous processes – be it oxygen input in wastewater technology fermentation in yeast production or cooling and combustion air for e.g. lime and cement production. Thanks to their high power density and reliability, the new packages keep life-cycle costs low and enable significant cost reductions.

About AERZEN

Industrial plants all over the world are supplied with gaseous media using AERZEN blowers and compressors. The innovative AERZEN machine technology represents experience gained over more than 160 years of company history. The AERZEN product portfolio includes rotary lobe compressors, positive displacement blowers, turbo blowers and screw compressors and, in addition to standard products, also offers customized special solutions. Digital services can be used to increase efficiency, availability and productivity in a sustainable and future-oriented manner. In addition, AERZEN After Sales Service offers the full range of services – from full maintenance contracts to repairs and modernizations of existing plants. For more information, visit https://www.aerzen.com.