By Uli Merkle, Busch Vacuum Pumps and Systems

03/17/2017

The Wastewater Association of Rheinfelden-Schwörstadt operates the wastewater treatment facilities in Schwoerstadt and Rheinfelden-Herten, Germany, as well as several rainwater overflow basins. The wastewater treatment facility in Rheinfelden-Herten has been in operation since 1980 and has been converted and reconditioned in recent years as a result to meet the latest technical standards. This wastewater treatment facility now satisfies the highest requirements, and with a population of about 47,000, has reached a size that also guarantees sufficient disposal capacity for future generations.

The wastewater treatment facility in Rheinfelden, Germany is the larger of two treatment facilities of the Wastewater Association of Rheinfelden-Schwoerstadt, which purifies 4,000 m3 of wastewater a day in dry weather and up to 25,000 m3 in wet weather. For ventilating the aeration channels, the facility relies on Tyr rotary lobe blowers from Busch, which provide the necessary injection of oxygen.

Thanks to a total investment of about $8.4 million in the latest technologies, the Wastewater Association has reduced pollutants further, which has a positive impact on the water quality of the natural watercourses. The methane gas produced in the digestion tower is used to power a gas engine in the facility’s own co-generation plant. The generator driven by this produces an average of 105 kW/h. This means that up to 50% of the energy required can be generated by the facility itself. In addition to this, the facility’s own heating system runs on sewage gas.

The aerobic biological wastewater treatment takes place after the primary settling tank in four aeration channels (Figure 1) with a total volume of 7,200 m3 and a depth of seven meters each. Each of these aeration channels is ventilated by a rotary lobe blower, which provides oxygen for the microorganisms in the wastewater to be treated. Air injection occurs via the aeration candles fitted on the bottom of the tank. In the downstream secondary settling tank, the microorganisms are separated as activated sludge particles from the treated wastewater and fed back into the aeration channels.

Figure 1. Four aeration channels with a total volume of 7,200 cubic meters ensure aerobic biological wastewater treatment at the wastewater treatment plant in Rheinfelden-Herten.

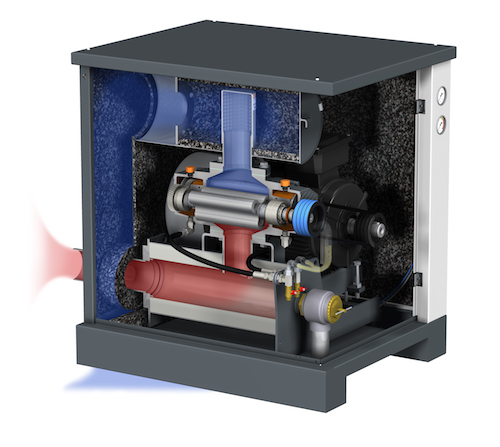

In 2008, new rotary blowers were purchased for the four aeration channels and another was installed as a replacement blower. After an operating time of several years, these blowers became increasingly fragile and the amount of maintenance and repair work increased. Operations Manager, Jürgen Nass, realized that the operational reliability was no longer guaranteed, so he searched the market for alternatives and came across the Tyr rotary lobe blower from Busch. He was advised by Busch and in June 2015 replaced one of the existing blowers with a new Tyr rotary lobe blower (Figure 2). This blower has been ventilating one of the four aeration channels ever since. Less than a year later, one of the existing blowers failed and, based on the good experience, Nass also replaced this with a Tyr rotary lobe blower (Figure 3).

Figure 2. Two Tyr rotary lobe blowers, with an output of a volume flow of 2,600 cubic meters per hour each, are in operation on each aeration channel.

Figure 3. Due to their modular design, Tyr rotary lobe blowers from Busch can be individually adapted to meet requirements.

All five blowers operate fully automatically via a PLC control system and are connected to the control system of the wastewater treatment facility. The oxygen content in each aeration channel is continuously measured using a sensor. If a minimum value is reached, the rotary lobe blower automatically switches on and ventilates the aeration channel until the oxygen reaches a predefined maximum value. Each blower is switched on and off around 15 times a day by this control system. The blowers are speed controlled. The intensity of the oxygen injection is regulated throughout the operating period, which is around 45 minutes at a time.

Tyr rotary lobe blowers are extremely user-friendly compared to conventional blowers. Oil levels in the gear and bearing unit can be checked outside via level indicators when the acoustic enclosure is closed. An oil change is simple to perform; as the oil-filling holes and the oil drain cocks are easily accessible once the door of the acoustic enclosure is opened. The inlet filter is fitted in such a way that it can be taken out without impurities being able to fall on the blower.

Nass also praises the reliability of Tyr rotary lobe blowers. After a year of operation, there has yet to be a single malfunction, let alone a failure. Therefore, he has no doubt that he will gradually replace all the blowers with the new Tyr rotary lobe blowers. His decision is reinforced by the fact that Busch is an extremely reliable partner that provides him with comprehensive support and advice. Busch offers Tyr rotary lobe blowers in several sizes and output classes, which means that the blower with the right output can be selected for each of the differently sized aeration channels.

About Busch

Busch Vacuum Pumps and Systems is a leading manufacturer and retailer of vacuum pumps, blowers, compressors and customized systems using vacuum technology. With over 50 years of experience and the largest selection of industrial vacuum pumps available today, Busch meets the demand for vacuum and pressure technologies in every industry across the world.

For more information, visit www.buschusa.com.

To read similar articles on Aeration Blower Technology, please visit www.blowervacuumbestpractices.com/technology/aeration-blowers.