11/09/2015

With the energy used by water and wastewater treatment plants in the United States accounting for 35 percent of a typical local government’s energy budget, GE formally introduced its new ZeeLung* Membrane Aerated Biofilm Reactor (MABR) technology that is four times more energy efficient than existing aeration systems. Aeration for biological treatment is the largest energy consumer in a wastewater treatment plant, typically representing 60 percent of a facility’s power usage.

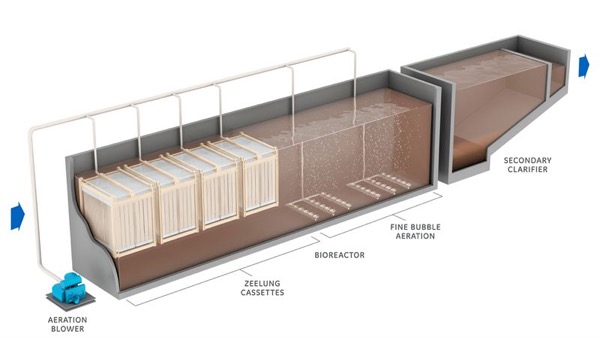

ZeeLung MABR technology is a simple solution that allows municipalities to achieve nutrient removal and/or capacity expansion in existing tank volumes while significantly reducing energy consumption. ZeeLung cassettes are immersed in existing bioreactors to improve treatment performance and/or increase treatment capacity without the need to expand the footprint of the facilities.

GE’s ZeeLung cassette provides low-energy nutrient removal in municipal wastewater.

GE developed the ZeeLung technology to enable wastewater treatment plants to achieve energy neutrality by significantly reducing the energy demand of the largest consumer in a treatment plant — biological process aeration. Coupling this energy reduction with enhanced on-site energy production from advanced anaerobic digestion can achieve energy neutral wastewater facilities — where the energy produced equals or exceeds the energy consumed.

“By inventing ZeeLung, GE is creating an opportunity to transform wastewater treatment plants from disposal facilities to resource recovery centers that yield clean water, nutrients and renewable energy from wastewater,” said Heiner Markhoff, president and CEO — water and process technologies for GE Power & Water. “This is a game-changing innovation in the pursuit of energy neutrality in the municipal wastewater treatment sector that also addresses the need for facilities to upgrade for nutrient removal and capacity expansion within an existing plant footprint.”

Municipal wastewater treatment plants are among the biggest industrial users of energy because they operate 24 hours a day, seven days a week. Publicly owned wastewater treatment systems use 75 billion kilowatt hours of energy annually, which is enough electricity to power 6.75 million homes. More than 3 percent of all electricity in the United States is used for wastewater treatment.

Close-up of GE’s ZeeLung membrane cord

In conventional biological treatment, fine bubble aeration is used to deliver oxygen to the microorganisms that metabolize the nutrients and organic pollutants in the wastewater. However, this approach is not efficient since most of the oxygen is wasted. To make this process more efficient, GE’s technology team developed the ZeeLung technology, which transfers oxygen by diffusion to a biofilm that grows on the outside surface of the membrane. The microorganisms in the biofilm remove nutrients and organics in the wastewater by metabolizing them in the presence of oxygen. The result is a four times reduction in energy compared to conventional fine bubble aeration systems in use today.

ZeeLung technology joins LEAPprimary*, Monsal* advanced anaerobic digestion as well as Jenbacher* gas engines in GE Power & Water’s portfolio of energy neutral wastewater treatment products.

Metropolitan Water Reclamation District of Greater Chicago Tests ZeeLung Technology

With the goal of becoming energy neutral by 2023, the Metropolitan Water Reclamation District of Greater Chicago (MWRD) recently began a demonstration project to evaluate GE's new ZeeLung* Membrane Aerated Biofilm Reactor (ZeeLung MABR) technology. The test is being performed at the district’s O'Brien Water Reclamation Plant in Skokie, Illinois, to prove ZeeLung’s ability to remove nutrients in the plant’s existing footprint and reduce the energy required for biological aeration by 40 percent.

The Metropolitan Water Reclamation District of Great Chicago’s O’Brien Water Reclamation Plant in Skokie, Illinois

Energy neutrality is the ability to reduce energy consumption while increasing energy production to the point that a facility produces as much or more energy than it consumes.

In June 2015, the MWRD and GE commissioned a demonstration of one ZeeLung MABR cassette at the O'Brien Water Reclamation Plant to prove the concept works — an important first step before the district considers whether to install the technology in the full-scale plant, one of the largest sewage treatment facilities in the United States.

Facing the need to meet more stringent regulations for phosphorus removal in the future, the MWRD was motivated to evaluate ZeeLung as a means to implement biological phosphorus removal in its existing bioreactors and without the need for chemical addition. Modeling has shown that at full scale, ZeeLung has the potential to help the MWRD improve the O'Brien facility’s performance under stressed conditions, specifically cold temperature peak events. Furthermore, these benefits come with the potential energy savings of 40 percent over the existing fine bubble aeration system.

“The energy costs for the O'Brien Water Reclamation Plant are $5 million per year. Our aspiration is to become energy neutral by increasing our energy production while decreasing energy consumption. GE’s ZeeLung has the potential to help us achieve this goal,” said Commissioner Mariyana Spyropolous, president of the MWRD Board of Commissioners. “The demonstration of GE’s new ZeeLung MABR may be an innovative way to meet the future regulation for phosphorous removal within the existing footprint while also decreasing the energy demand of the plant.”

ZeeLung is a gas-transfer membrane, which transfers oxygen by diffusion to a biofilm that grows on the outside surface of the membrane. The microorganisms in the biofilm remove nutrients and organics in the wastewater by metabolizing them in the presence of oxygen. The result is a four times reduction in energy compared to conventional fine bubble aeration systems in use today.

Close-up of GE’s ZeeLung membrane cord at the Metropolitan Water Reclamation District of Greater Chicago’s O’Brien Water Reclamation Plant

“The future of wastewater treatment is energy neutrality, and ZeeLung MABR will help local governments save energy while improving nutrient removal within the existing plant footprint. The Metropolitan Water Reclamation District of Greater Chicago is the first municipality to demonstrate ZeeLung. In just a few short months, the O'Brien Water Reclamation Plant already has achieved significant results in proving the ZeeLung concept,” said Heiner Markhoff, president and CEO — water and process technologies for GE Power & Water.

The O'Brien Water Reclamation Plant began operation in 1928 and was a model for modern sewage treatment technology. The facility serves more than 1.3 million people residing in a 141-square-mile area, which includes the city of Chicago, north of Fullerton Avenue, and the northern Cook County suburbs. It removes pollutants from wastewater through primary clarification and conventional activated sludge and has a design capacity of 333 million gallons per day.

For more information, visit www.ge.com.

To read more articles on Wastewater please visit: www.blowervacuumbestpractices.com/industries/wastewater.